The Best Products

How is the glue roller made

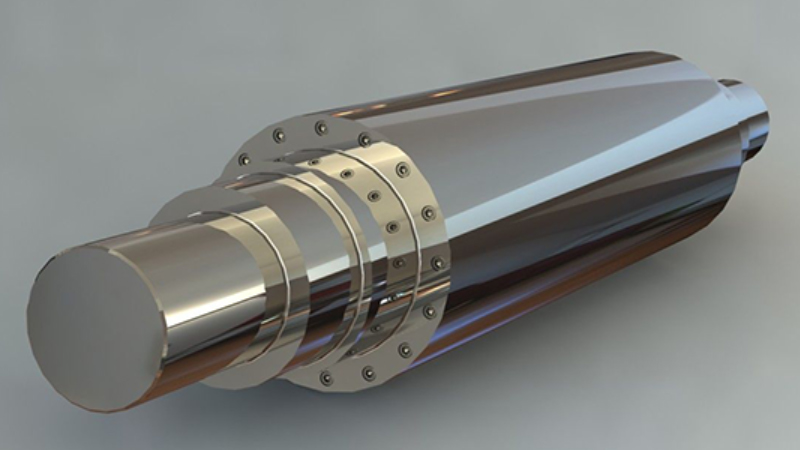

Glue wrapping roller is a type of roller widely used in printing, transportation, metallurgy, textile, papermaking and other fields, and its quality directly affects the operation of the production line. The production process of the glue roller is relatively complex, mainly divided into the following steps.

1、 The production of roller cores selects the appropriate size of the roller according to the size of the glue coated roller as the roller core. The material of the core of the glue wrapping roller is usually stainless steel, carbon steel, etc. After the roller core is processed to the specified size, sandblasting treatment is also required to ensure that the rubber layer adheres better to the surface of the roller core,

2、 Refining rubber

Choose the appropriate rubber as the adhesive layer for the rubber roller. Different rubber materials correspond to different production requirements. Usually, the rubber on the outer layer of the rubber roller is EPDM, polyurethane, silicone rubber, etc. After adding auxiliary agents, vulcanizing agents, and other materials to the selected rubber, it is put into a rolling machine for compounding.

3、 Encapsulation adhesive

Glue wrapping, also known as adhesive layer wrapping, is usually used in two ways: cold wrapping and hot wrapping. Hot pack, the rubber adopts the hot vulcanization coating process, which is suitable for high precision rubber rollers. The cold pack adhesive adopts the method of wrapping the adhesive layer after applying adhesive water, which is more suitable for the adhesive in the mining industry.

4、 Rubber roller vulcanization

The roller after encapsulation still needs to undergo vulcanization treatment. Vulcanization can remove toxic substances from rubber and make it less prone to cracking.

5、 Rubber roller grinding

Grinding is the final step in the rubber roller manufacturing process, which enables the rubber roller to meet the required dimensions and surface roughness,

Previous: How to extend the service life of rubber rollers?

Next: No More