The Best Products

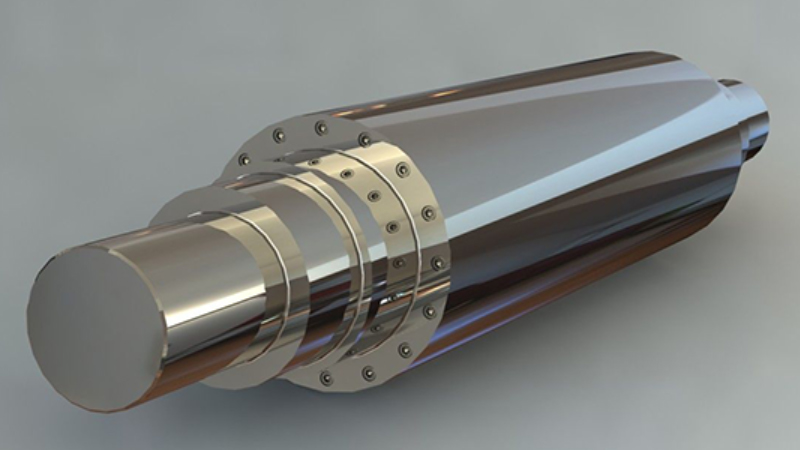

How to extend the service life of rubber rollers?

Many equipment manufacturers do not know how to properly maintain the rubber rollers after installation. Doing the following can help you extend the service life of rubber rollers.

1. Newly manufactured rubber rollers should not be used immediately. Due to the rubber roller just being prepared, it needs to be left for a period of time. Ensure that the rubber roller is in contact with a certain environment and humidity conditions in order to maintain a stable state and enhance the durability of the rubber roller.

2. Properly storing rubber rollers can extend their service life. When not using rubber rollers, the rubber rollers should be cleaned, packaged, and stored on the rubber roller rack. The storage of rubber rollers should be careful not to collide or pile up with other rollers, which may cause surface wear or bending of the rollers. The storage location of rubber rollers should also be kept dry and ventilated to avoid moisture and rust on the rollers.

3. The rubber roller shaft head and bearings should be well lubricated. Regularly inspect the lubrication of the rubber roller bearings and add lubricating oil in a timely manner, otherwise poor lubrication of the rubber roller bearings can cause bearing wear and even affect production efficiency.

4. Regularly clean the surface of the rubber roller. Due to the special application of rubber rollers, the surface of rubber rollers in papermaking, printing, textile and other fields is prone to accumulating stains such as dyes and ink. Therefore, regularly cleaning the surface of the rubber roller can ensure the printing and dyeing quality of the rubber roller. It should be noted that professional cleaning agents should be used when cleaning the surface of the rubber roller to ensure the cleaning effect. Overall, regular maintenance of rubber rollers can extend their service life, reduce production costs, and improve production efficiency.