The Best Products

What are the classifications of heating rollers

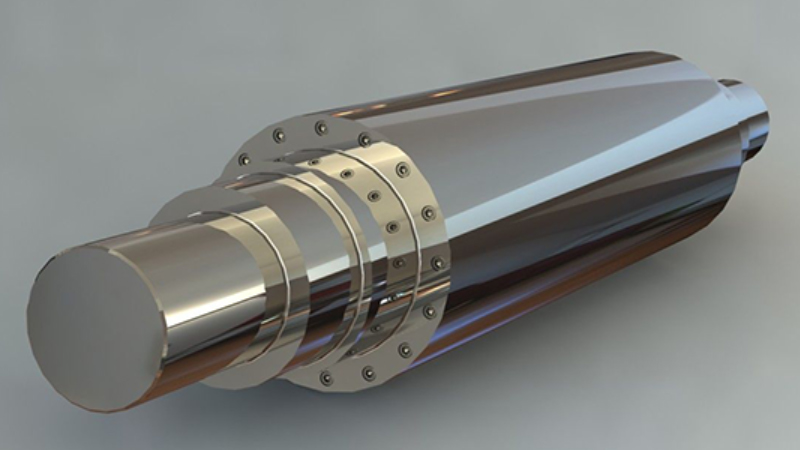

A heating roller is a type of roller that can generate heat through external forces and rotate to transfer heat energy to other objects. Heating rollers are widely used in fields such as textiles, printing, plastics, printing, and papermaking, mainly for heating processes in production processes.

According to different usage conditions, the heating roller also has different heating methods. The heating methods of the heating element mainly include fluid heating and electric heating. Among them, the fluids used for fluid heating mainly include thermal oil, water, and steam, while electric heating uses electromagnetic heating or electric heating. Different heating methods will also affect the material and structure of the heating roller. The following are several classifications of heating rollers.

1. Heat transfer oil heating roller

This type of heating roller is quite common, and its advantages are simple structure and convenient manufacturing. Due to the use of thermal oil for heating, the temperature of the heating roller can reach around 250 ℃. The interior of the heating roller is prone to scaling and there is a risk of oil leakage.

2. Water heating roller

The heating principle of a water heating roller is that as the water temperature rises, the temperature of the heating roller also increases. Its structure is similar to a thermal oil heating roller, and the temperature of the water heating roller does not exceed 100 ℃, making it suitable for industries with low temperature requirements.

3. Steam heating roller

Through the connected pipeline, steam is introduced into the roller, thereby achieving the effect of heating the roller. Due to the influence of steam temperature and steam pressure, steam heating rollers are also more suitable for industries with low temperature requirements.

4. Electric heating roller

The heating source for electric heating rollers is usually an electric heating rod. The electric heating rod and the roller are not in direct contact, and the heat transfer between them is usually done through conduction and radiation. In theory, this heating method can bring the roller to a very high temperature, but if the heat transfer problem is not handled properly, the uniform heating effect cannot be achieved.

5. Electromagnetic induction heating roller

The manufacturing of electromagnetic heating rollers is difficult and requires a high level of technical expertise. The advantage of this heating roller is that it can achieve high temperature heating and control the temperature according to actual needs,