The Best Products

The benefits of roller tungsten carbide spraying

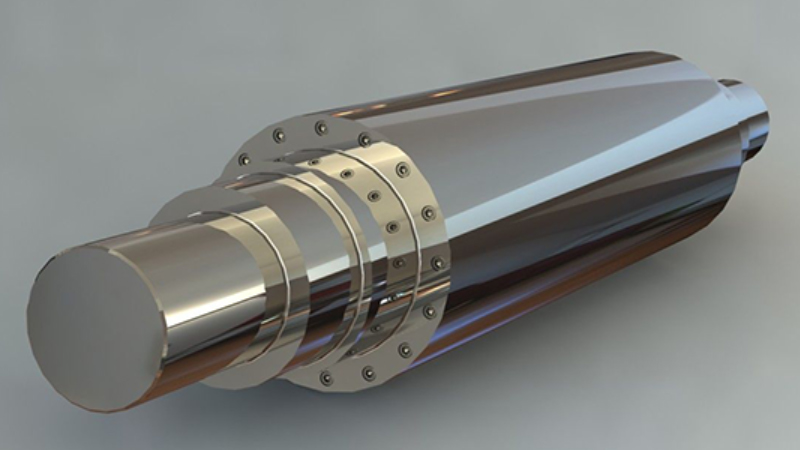

In order to meet certain industry requirements, the surface of the roller requires tungsten carbide spraying treatment. Tungsten carbide roller is a roller formed on the surface of tungsten carbide using thermal spraying technology. By using high temperature to unmelt tungsten carbide powder, it is sprayed onto the surface of the roller using a high-speed spray gun to form a high-performance coating. The following are the benefits of roller tungsten carbide spraying.

1. Improve wear resistance. The tungsten carbide roller has a special coating that can resist the wear of other objects under high-speed rotation, and has good wear resistance.

2. Improve the toughness of the roller. Compared with rollers that have not been sprayed with tungsten carbide, the surface of tungsten carbide rollers has excellent toughness, which can effectively reduce the cracking and deformation of the rollers during use.

3. Improve the hardness of the roller. One of the benefits of tungsten carbide spraying on the surface of the roller is to improve hardness, effectively resist wear, and ensure the long-term service life of the roller.

4. Enhance high temperature resistance. Tungsten carbide rollers can maintain stable mechanical properties in higher temperature environments and are not easily deformed.

5. Extend the service life of the roller. The excellent performance of tungsten carbide rollers enables them to maintain stable performance in various environments, resist various corrosion and wear, and provide long-term guarantee for production and processing quality.